Ellisbridge, Ahmedabad, Gujarat

- GST NO. : 24AAWPP5303P1Z1

Welding Machine

Leading Manufacturers, Exporters, Wholesaler of Ultrasonic Hand Welding Machine, Ultrasonic Plastic Welding Machine, Auto Ultrasonic Drip Chamber Welding Machine, Auto Velcro Cutting & Welding Machine, Ultrasonic Double Head Non Woven Bag Handle Welding Machine and Ultrasonic Single Head Non Woven Bag Handle Welding Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Model | SE-201200 |

| Voltage | 220V 50/60Hz |

| Power | 1200w |

| Frequency | 20KHZ |

| Material of horn | Titanium alloy |

| Welding Horn | Customized as your request (40*50mm) |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier |

| Weight | 280KG |

| Voltage | 220V |

| Power | 2000W |

| Frequency | 20KHZ |

| Model | SE-SD1526 |

| Size | 1500 * 1500 * 1850mm |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

Auto Rotary Ultrasonic Welding Machine uses ultrasonic welding and auto sealing after cutting, mainly used for the edge welding and cutting processing in cup type face masks production, melted the two independent processing edge welding and edge cutting creatively compared with the traditional way, multi working position turntable, with both welding and cutting device which will work at the same time, with PLC control and touch screen, convenient and easy for operating, each machine need only one worker with feeding and pick up the finished products, can greatly saves labor cost, and improves the production efficiency and makes the production of cup type face mask more easy.

Features and Function

- High welding efficiency, batch processing can be welded plastic parts.

- Do not need any auxiliary, chemical solvents, so there is no impact on human health.

- Firmly bonded, no distortion, does not affect the appearance, without damaging welding object.

- Guarantee to be welded airtight, watertight.

- Imported piezoelectric ceramic transducer, output strong and stable.

- None auxiliary material, harmless;

- High air tightness and water tightness;

- Piezoelectric ceramic transducer imported, output is strong and stable;

- Anti-backwards and coaxial direct pressure design, pressure exerted evenly, improve welding precision;

- Touch screen, parameter set intuitional and exact;

- Imported main electrical components;

- Sophisticated PLC control circuit, automatic overload protected system;

- High precision segmentation imported from Taiwan, no error; NC switch, progress up to 0.01;

- Unique design of level screw, mould is easier to debug;

- High Q value transducer, output power strong;

- Turbine design, adjust trip easily; alloy amplitude transformer, strong and stable ultrasound

- Electrical components, high performance.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Model | SE-ADD3550 |

| Voltage | 220-240V/50-60Hz |

| Power | 5KW |

| Frequency | 35KHZ |

| Size | 2300 * 1500 * 1950mm |

| Weight | 800KG |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

The Auto Ultrasonic Drip Chamber Welding Machine uses ultrasonic technical for welding drip chamber and filtering membrane. Manipulator plus conveyor structure which can save 4~5 workers each machine compares to traditional plastic welding machine. Welding Processing: Manual Feed- Bottom Die Transfer-filter membrane input-ultrasonic weld-auto check-auto material return

Features and Function

- Original imported PLC + Chinese & English LCD displayer

- Servo motor for accuracy belt transferring controlling and positioning

- Punching dies are made of imported die steel, imported machine for WEDM-LS, high precision die and without deckle edge and durable at the same time.

- Matched with imported ultrasonic welder to get more stable welding effect, low reject rate and longer service life.

- High accuracy air leakage checking system to make sure the high acceptability of finished products

- Belt transferring to get more efficient and safe welding

- Incomplete filling induction device, no filter input, no welding and no stop once there is no plastic parts in the right position.

- No need any other auxiliary material, no need chemical liquid, so it’s safe for workers.

- Strong welding, no transformation, no appearance harm and no welding damage.

- Can reach air tightness and water tightness.

| Business Type | Manufacturer, Exporter, Supplier |

| Model | SE-MJH1520 |

| Voltage | 220V 50/60 Hz |

| Power | 2KW |

| Frequency | 15KHZ |

| Weight | 40KG |

| Productivity | 15-25 pcs/min |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

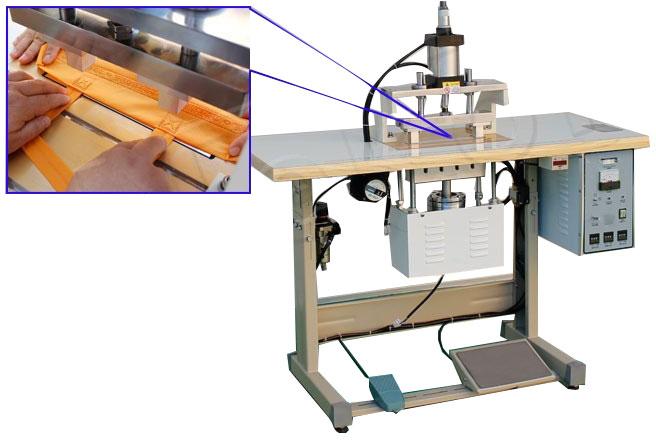

The Auto VELCRO cutting & welding machine can cut and weld the VELCRO piece as its name: first cut the VELCRO into required length then fold and weld one end with ultrasonic to make it a ring then can be used as a VELCRO cable ties/VELCRO cable strap, for example cable tie of NOKIA PHONE charger, cable strap of laptop adapter and so on.

Also be called as: auto magic tape cutting & welding machine, auto hook and loop cutting & welding machine, auto VELCRO cable ties cutting machine, auto VELCRO cable strap cutting & welding machine, auto VELCRO cable ties making machine, auto ultrasonic VELCRO cable ties machine and so on.

Features and Function

- High precision: feeding with step motor which can control the accurate measurements.

- Flexible applicability: can cut VELCRO cable ties into different length without change any spare parts

- Independent bodies of the machine which can be set out related.

- PLC control, easy and convenient in operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Model | SE-GW2003 |

| Voltage | 220V |

| Size | 1200*720*1450mm |

| Weight | 145KG |

| Production | 8pcs/min |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

The Nonwoven tote bag welding machine weld hands pull to the bag directly by using ultrasonic principle. Pneumatic device to insure Welding quickly if switch step down, beautiful and stable welding point, Design all kinds of welding dark fringe if you required. Adjusting welding width is available within the mould’s length. Length of hands pull is not limited, starting up working directly without preheat, high efficiency, only two persons could operate this unit for enhancing efficiency and deduce labor.

Features and Function

- Improved design optimal performance

- Japan imported transducer, strong and stable output

- Titanium transducer, longer useful life

- Automatic compensation circuit of frequency modulation and frequency

- Set the soft start circuit debugging, to avoid damage to the mold

- The whole machine body processed by CNC tool, high precision

- Adjustable floor structure, debugging mold conveniently

- All of high-quality imported parts components, quality assurance

- Welding, high efficiency, low non-performing

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Model | SE-GW1003 |

| Voltage | 220V |

| Size | 1200*720*1450mm |

| Weight | 145KG |

| Production | 8pcs/min |

| Brand Name | SHEETALSONIC |

Preferred Buyer From

| Location | Anywhere in India |

The Nonwoven bag welding machine weld hands pull to the bag directly by using ultrasonic principle. Pneumatic device to insure Welding quickly if switch step down, beautiful and stable welding point, Design all kinds of welding dark fringe if you required. Adjusting welding width is available within the mould’s length. Length of hands pull is not limited, starting up working directly without preheat, high efficiency, only two persons could operate this unit for enhancing efficiency and deduce labor.

Features and Function

- Improved design optimal performance

- Japan imported transducer, strong and stable output

- Titanium transducer, longer useful life

- Automatic compensation circuit of frequency modulation and frequency

- Set the soft start circuit debugging, to avoid damage to the mold

- The whole machine body processed by CNC tool, high precision

- Adjustable floor structure, debugging mold conveniently

- All of high-quality imported parts components, quality assurance

- Welding, high efficiency, low non-performing